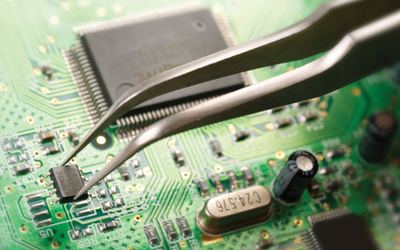

The reality is that no soldering operation produces perfect assemblies everytime. Even the highest quality components fail from time-to-time. That’s why ITW Contamination Control offers two of the top brands in the electronics to meet all your electronics repairs & prototyping needs. All these products are engineered to make your circuit board and PCB repair process more efficient and effective.

Overview

ITW Contamination Controls electronics department has the complete line of conveniently packaged and precision dispensing rework and repair products, improving faster, easier and more accurate. The unique pen delivery system ensures performance and pinpoint accuracy. The full range of products meets the technicians needs.

Flux is used to clean the surface of PCBs before the soldering process. It helps to remove oxides and other impurities which helps the wetting procedure. The flux pens provide controlled and exact applications, decreasing the excess amount of flux which eventually decreases the amount post-cleaning.

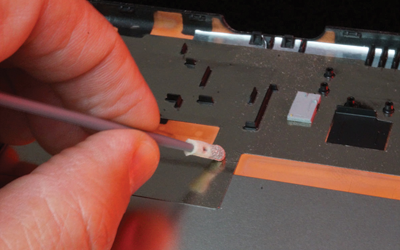

In essence a very simple product, but an integeral part within our electronics product family. With good reason. They’re the cleanest and safest braid in the industry, decreasing the risk of heat damage on the board. Therefore, desoldering braids should be a mainstay in your electronics repair and prototyping kit.

To be able to provide a turn-key solution within the electronics industry, it has been important to also provide solutions to repair traces and solder while avoiding high temperatures. ITW Contamination Control offers Conductive Pens and Paints through its CircuitWorks brand. Easily dispense and apply conductive material such as silver or nickel where repairing is necessary. Therefore, CurcitWorks comprehensive line makes circuit board repair and prototyping faster and easier.